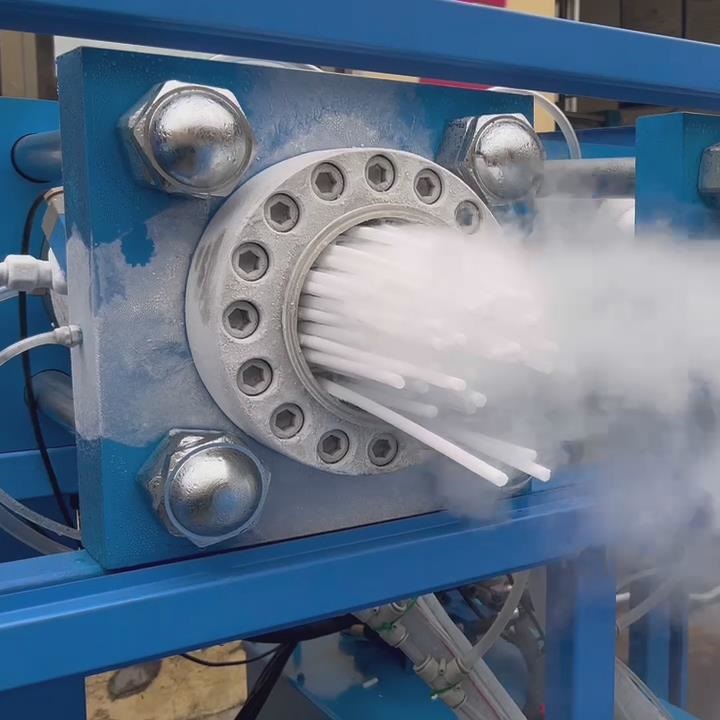

The automotive circuit is one of the most important parts in a car, but due to its complexity, cleaning it is very tedious and time-consuming. However, the emergence of dry ice cleaning technology has brought revolutionary changes to the cleaning of automotive circuits. Here are five advantages of using dry ice to clean automotive circuits. Dry ice can be used for live operation: Traditional automotive circuit cleaning requires disassembling automotive components, while dry ice cleaning technology can be used for cleaning without disassembling automotive components, and even work with live circuits, greatly improving cleaning efficiency. Significant cleaning effect: Dry ice cleaning technology can quickly and effectively clean various dirt and oil stains in automotive circuits, such as oil stains, dust, rust, etc., thoroughly cleaning the circuits and ensuring the normal operation of automotive circuits. Environmental protection and energy conservation: Dry ice cleaning technology does not require the use of chemical cleaning agents, only dry ice particles are used for cleaning, so it will not cause pollution to the environment and also saves energy, which is in line with the modern concept of environmental protection and energy conservation. Easy and convenient operation: Dry ice cleaning technology is easy and convenient to operate, just spray dry ice particles on the car circuit that needs to be cleaned, without the need for complex equipment and technology, reducing the difficulty and time cost of operation. Economical: Dry ice cleaning technology has significant cleaning effects, simple and convenient operation, which can significantly reduce cleaning costs, improve cleaning efficiency, and also extend the service life of automotive circuits. It is an economical cleaning method.

Can dry ice summon wind and rain?

In some special scenarios, dry ice seems to have the