Dry ice blasting is a new cleaning technology developed in recent years, which has been widely used in various industries, replacing part of the traditional cleaning method. Among them, waste heat boilers in cement industry benefited much from using dry ice blast cleaning .

What is the waste heat boiler ?

Waste heat boiler, use the waste heat produced during a variety of waste gas or waste liquid industrial processes , as well as the heat generated after the combustion of waste materials, to heat the water to a certain temperature, then through the recycling of hot water or steam to supply other sections. In order to achieve energy conservation and environmental protection, improve enterprise efficiency.

The essence of waste heat boiler is a gas- water/steam heat exchanger, someone directly called water heat exchanger.

Case analysis Of Dry Ice Blasting Cleaning Boilers

The application of waste heat boiler in cement industry has been quite mature, but cleaning has always been a big problem for enterprises to solve, so we promote dry ice blasting cleaning, bringing good results.

In the process of boiler operation, solid particles such as carbon powder, sulfide and minerals in flue gas are continuously deposited on the surface of fins or nail heads on the outer wall of furnace tube, in convection section. Meanwhile, corrosive media such as SO2 in flue gas have certain corrosive effect on furnace tube, resulting in corrosion products also adhere to the surface of furnace tubes.

With the extension of boiler operation time, the surface of the furnace tubes accumulated more and more dirt, sometime ash filled the gap of the furnace tubes, the fins and nail heads of the furnace tubes can not be seen. This greatly reduced the heat transfer performance of the convection section , and increased the thermal resistance.

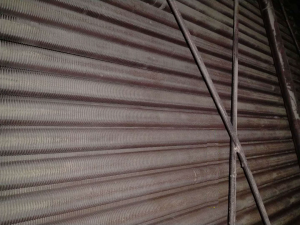

This is a picture of the furnace tubes of an oil refinery before dry ice blasting. It can be seen from the figure that ash accumulation in coking furnace is very serious, and the actual scale thickness is more than 7mm. In this way, the thermal resistance of scaling outside the finned or nailed tube is increased by more than 5 times under the condition that the thermal conductivity of scaling remains unchanged. What a serious problem .

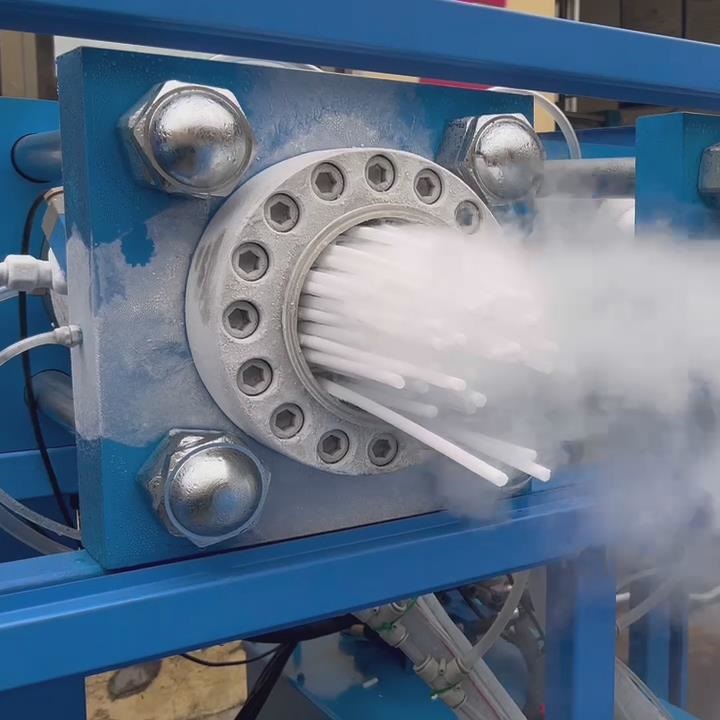

This is a picture of the furnace tubes after dry ice blasting cleaning. It is clear that the dirt has been completely removed and the fins are clearly exposed. The furnace temperature and the inlet & outlet temperature of the furnace tubes meet the requirements of the process index again, which solved a big problem for the enterprise and improved the economic benefit.

During this process , our cleaning team used the model WT-750B , economical and practical type , widely used in kinds of industry cleaning . Are you interested ?