When it comes to dry ice blast cleaning technology, it has become more and more popular in recent years, but there are still many friends who do not know much about it.

What is Dry ice blast cleaning ?

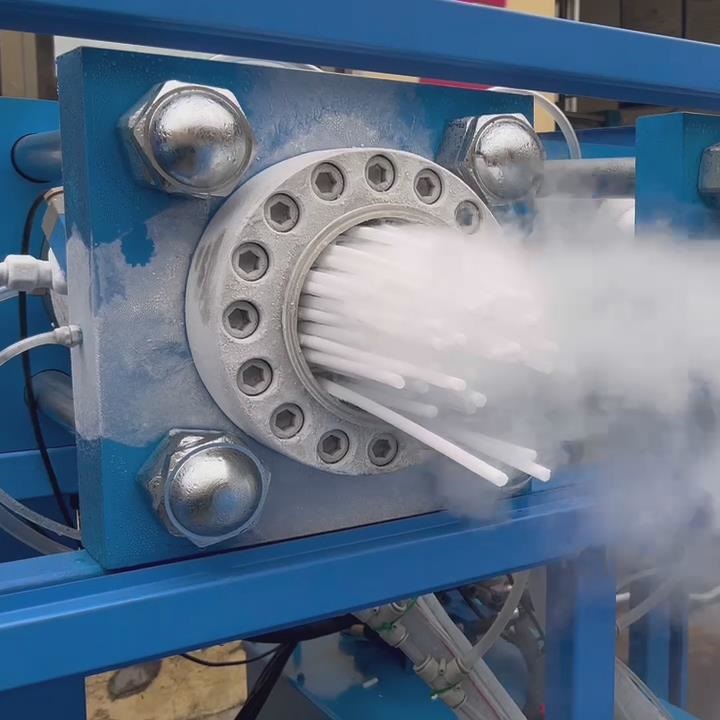

Dry ice cleaning technology is currently widely used in industrial cleaning ,mold cleaning, tire casting industry,etc., has become the official cleaning method . It use a specific dry ice pellets making machine to prepare dry ice particles in 3mm diameter . Dry ice particles are sprayed onto the surface of the substrate by high-speed nozzle of the dry ice blasting machine for cleaning treatment.

3 Basic working principles

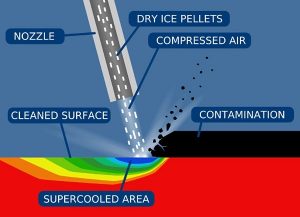

Dynamic effect: When dry ice particles hit a surface at the very high speed like sound’s , any foul layers on the surface will be break and loosen .

Thermal impact effect: This is caused by the natural nature of dry ice, where the inherent ultra-low temperature causes the contaminant layer to shrink and embrittlement and be removed. The temperature gradient orΔT between the pollutant and the surface of the base material will make the pollutant produce microcracks quickly, which will destroy the adhesion between the pollutant and the base material. This is caused by the different thermal expansion and contraction coefficient of different materials.

Blast effect: The rapid heat transfer causes the dry ice particles to sublimate instantaneously, and the sublimated gas expands to nearly 800 times in volume within milliseconds. This effectively creates a continuous burst between the microlayers at the point of impact, known as a microburst. This extremely efficient energy allows the dirt to be removed from the workpiece surface.

It is because of these three effects that dry ice blast cleaning can effectively clean stains, and the effect is great .

6 Advantages of Dry ice blast cleaning

Without water cleaning , Non-Residues . Dry ice evaporates immediately during the cleaning process, leaving no residue. This method is very suitable for dry cleaning industries, such as food processing and electrical and electronic equipment, etc .

Deeping cleaning , and Non-abrasive . Dry ice blasting can effectively clean corners and cracks that are difficult to reach by other traditional cleaning methods. It does not require abrasive cleaners to be added to avoid damaging the integrity of the surface of the equipment.

Operate online . Dry ice cleaning can be directly online cleaning, machine running state can also remove stains on the machine, improve the efficiency of cleaning, while greatly reducing the downtime.

Easy to operate. After a dry ice cleaning machine is connected to an air compressor, the cleaning operation can be carried out, and the process is simple and safe.

Fast cleaning . Traditional cleaning is a waste of time, while dry ice cleaning is more faster and can save time, greatly improve work efficiency, and meet the needs of more industries.

Save cleaning cost. There is no additional cost for cleaning products and secondary treatment.

A dry ice blast cleaning machine generally need two workers to assist each other to complete the cleaning operation, which is efficient and convenient and save labor costs.

We- Wantong, provide different power grade dry ice blasting machine to suit for different cleaning field conditions , with good quality and high efficiency .

Welcome to view our YouTube , there will be more cleaning videos . Here is a cleaning video for reference: https://www.youtube.com/watch?v=9G_ph36OfUg