What is Carbon Capture utilisation and Storage—CCUS ?

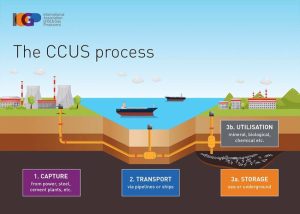

Carbon Capture utilisation and Storage (CCUS) : Capture carbon dioxide released into the atmosphere, use a range of technologies to purify, separate, compress, and pump it back into depleted oil and gas fields or other safe underground sites.

Compared with direct emissions, CCUS can greatly improve the storage efficiency of CO2. It is generally believed that the efficiency can reach 99% and last more than 1,000 years. Therefore, CO2 CCUS technology has a broad application prospect and is one of the most economical and feasible solutions.

Here is an article that describes this technique more fully : What is CCUS and why is it necessary?

CCUS tech used in Cement industry

It is well known that the production of cement, the world’s most dominant building material, is a major source of greenhouse gas emissions, accounting for about 8% of all such emissions. If cement production were a country, it would be the third largest emitter in the world.

The main source of carbon emission in cement industry is the high temperature calcination of mature materials by limestone (calcium carbonate) and the release of carbon dioxide. However, the carbon emission in this process is relatively fixed, and it is difficult to implement carbon emission reduction through technological transformation and other means.

Given that carbon neutrality is not a complete ban on any greenhouse gas emissions, only a dynamic balance of carbon dioxide emitted into the air and taken out of the air is required, carbon capture technology-CCUS tech can be developed in the future to hedge against industrial processes that cannot be decarbonized.

Process of Carbon capture utilisation and storage- CCUS

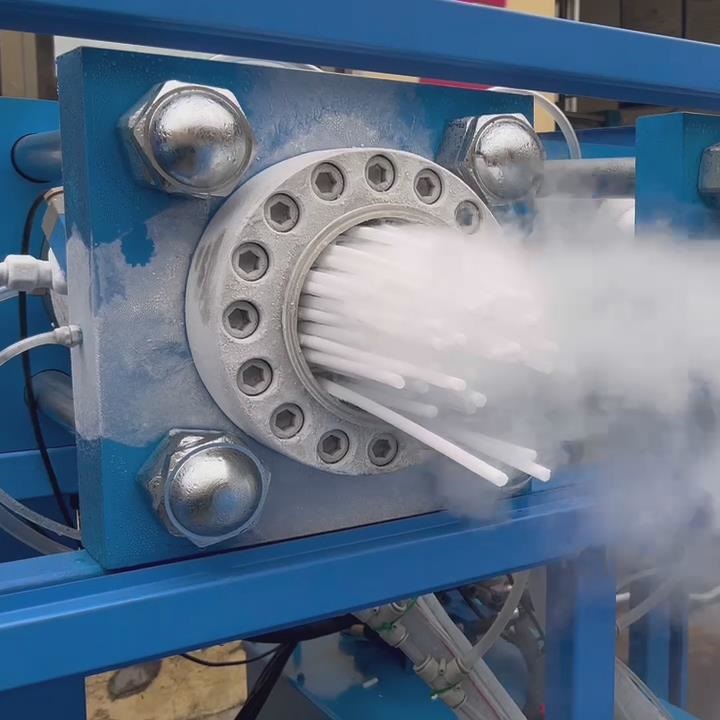

Carbon capture

CO2 capture refers to the process of separating CO2 from flue gas produced by fossil fuel combustion and compressing it. The main targets of carbon capture are concentrated CO2 emission sources such as fossil fuel power plants, steel plants, cement plants, oil refineries and ammonia plants.

At present, there are three kinds of capture and separation systems for fossil fuel power plants, namely, post-combustion capture system, pre-combustion capture system and oxidized fuel capture system.

Carbon transport

Transport of CO2, which refers to the transport of separated and compressed CO2 to storage by pipeline or vehicle. The first long-distance CO2 pipeline went into operation in the early 1970s.

Carbon sequestration

Storage of CO2 refers to the injection of CO2 transported to the storage site into geological structures such as underground brine layers, abandoned oil and gas fields, coal mines, or deep seabed or geological structures below the seabed.

Take China as an example to see the world, development prospects of CCUS Technology

In recent years, China has been striving to achieve the goal of carbon neutrality.

In October 2018, the 50,000-ton CO2 capture, collection and purification demonstration project of Baimashan Cement Plant invested by Conch Cement and Dalian University of Technology in the mode of industry-university-research cooperation was completed and put into operation, which can simultaneously produce 99.9% industrial and 99.9% food grade CO2 products. It can produce 30,000 tons of food grade and 20,000 tons of industrial grade carbon dioxide every year, which is widely used in carbonated beverage addition, food and vegetable preservation, dry ice production raw materials and other fields.

At present, it is difficult to apply CCUS technology on a large scale, on the one hand, the technical level still needs to be improved, our CCS experimental demonstration is still in its infancy, lack of large-scale, whole process demonstration experience. CCS demonstration projects, on the other hand, all cost hundreds of millions of dollars, and with existing technologies, the introduction of carbon capture will add some extra operating costs per tonne of CO2.

In the long run, carbon capture technology-CCUS tech is the core link to achieve carbon emission reduction in cement industry, which has a large proportion of carbon emissions from raw materials. With the continuous progress of technology and the reduction of cost, carbon capture technology is expected to help cement industry achieve carbon neutrality.