In the field of equipment cleaning, a revolution is quietly emerging. The traditional chemical cleaning method, although solved some of the dirt problems for a period of time, now its drawbacks are becoming increasingly apparent. It is time to say goodbye to it and embrace the new technology of green dry ice cleaning.

Chemical cleaning relies on a large amount of corrosive chemical agents, which, while removing dirt, act like “double-sided blades” mercilessly eroding the metal surface of equipment, greatly reducing its lifespan. Moreover, the treatment of residual chemical agents after cleaning is extremely difficult, and even a slight carelessness can cause soil and water pollution, bringing heavy pressure to the ecological environment.

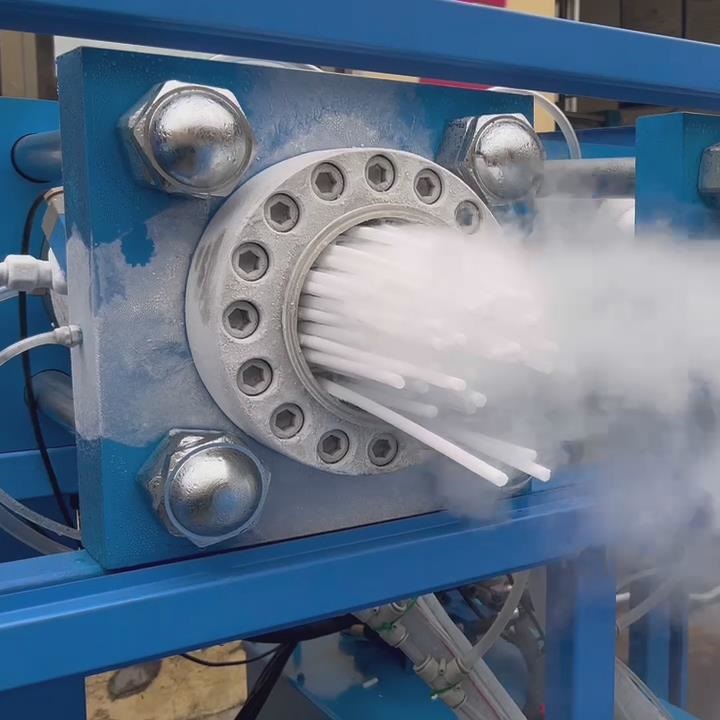

In sharp contrast, green dry ice cleaning. Dry ice cleaning utilizes the low-temperature and easily sublimated characteristics of dry ice particles to rapidly impact equipment surface dirt. Dry ice instantly transforms from a solid state to a gas state, and its volume expands to generate strong peeling force, uprooting dirt and achieving excellent cleaning effect. No chemical agents are required throughout the process, completely eliminating the risk of corrosion and perfectly protecting the integrity of the equipment.

At the same time, after sublimation, dry ice directly returns to the atmosphere and turns into carbon dioxide, without producing any harmful waste, which is both environmentally friendly and safe. In industries such as food processing and electronic manufacturing that require high hygiene and precision, dry ice cleaning is the best choice, making the cleaned equipment as clean as new without any chemical residue concerns.

Choosing green dry ice cleaning is a crucial vote for the health of equipment, ecological environment, and sustainable development of enterprises, opening a new chapter of cleanliness and efficiency.